Baffles

Importance of baffles

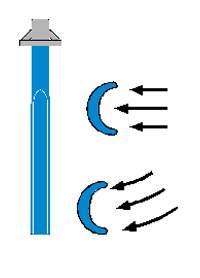

Baffles are needed to stop the swirl in a mixing tank. Almost all impellers rotate

in the clockwise or counter-clockwise direction. Without baffles, the tangential

velocities coming from any impeller(s) causes the entire fluid mass to spin. It may

look good from the surface seeing that vortex all the way down to the impeller, but

this is the worst kind of mixing. There is very little shear and the particles go

around and around like in a Merry-Go-Round. This is more like a centrifuge than a mixer. The presence of baffles stops that. This page is dedicated to the variety of baffles and the effects of their dimensions.

|

|

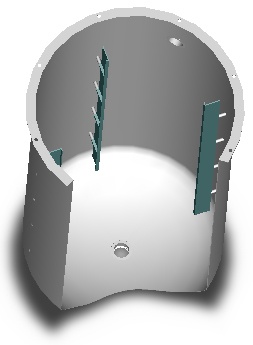

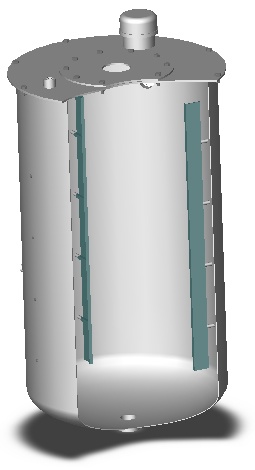

Baffle schematics courtesy of

P. Csiszar

|

Most common baffle types

Most common baffles are straight flat plates of metal that run along

the straight side of vertically oriented cylindrical tank or vessel. This

baffle design is often referred to as "standard baffles". There are

many nuances. Some may have the baffles extend into the bottom dish or

bottom head. Some may go up the straight side only partially (so-called

partial baffles). Some baffles are flush with the side wall, but the

majority have a space between the baffles and the tank's wall. They are

off-wall.

Number of baffles

Most vessels will have at least 3 baffles. 4 is most common and is

often referred to as the "fully baffled" condition. This basically means

that adding any more baffles doesn't significantly add to the power

consumption of the impellers.

|

|

Baffle width

Baffle width, wB, is a function of the viscosity. For very high viscous

fluids and broths, baffles are not even required, because there is enough

resistance to flow at the walls. As the viscosity decreases, baffling

becomes important and the baffle width gets larger. Guidelines for baffle width as a function of viscosity

will be here soon.

|

|

In turbulent flows two standards of baffle widths have emerged: Metric

standard(wB=1/10) and the American standard (wB

=1/12). The difference is not large, but it is worth noting. Since the metric

system is built on tenths, it is easy to determine baffle width. If the tank

diameter, T, is 3 meters, then the baffle width is 300 mm. Simple, right? That is

not so simple in those countries using inches and feet for linear dimensions. 1/10th

of 9 feet is 0.9 feet and is not easily converted to inches. Using the 1/12th

rule (0.083), the baffles for a 9 foot tank will be 9 inches in width.

It is important to understand this small difference, 0.083 vs. 0.1,

when looking at power numbers and flow patterns. If the author of the

paper comes from Europe, Asia, or Africa, chances are that the Metric standard

is used (1/10). North American, Central American, South American, and British

may be using the American standard (1/12).

Baffle height

Most baffles start at the bottom tangent line of the lower head and run up to

the top tangent line of the upper head. Some do extend down into the head. If

you have consistent batch volumes or weights, it is best not to extend the

baffles through the liquid surface, unless you want to entrain air into

the batch. Baffles extending through the surface can create vortexes behind

the baffles and entrain air. In viscous media, the baffles can create dead zones

on the surface, and pack-up the material in front of the baffle (in

flow direction). If you are adding sticky solids on the surface, the baffles are

a great place for materials to agglomerate.

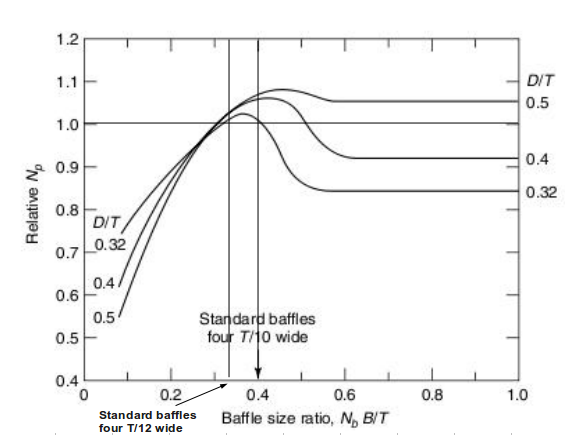

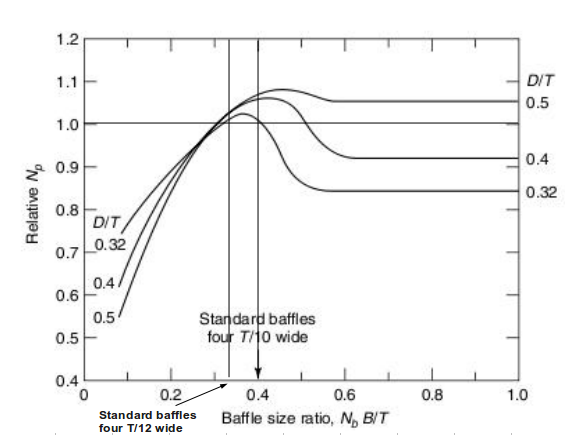

Effect of baffles on the impeller power, the Baffle Factor, or BF

The effect of baffles on the power is often described as the baffle factor, or BF. As you can imagine, 4 baffles will cause the impeller to draw more power than if there were only 3, 2, 1, or no baffles present. The baffle factor is a factor multiplied with the fully baffled, turbulent power number Np, to achieve the apparent power number of the mixer. The Handbook of Industrial Mixing (2004), has a figure (Figure 6-15, page 362) that shows what BF is as a function of baffle configurations. Unfortunately, that figure's X-axis is wrong. Here we show the corrected graph.

The baffle factor in this graphic is labeled Relative Np (Y-axis). The Baffle size ratio, is a dimensionless number consisting of the number of baffles, Nb, the baffle width (here as B), and the tank diameter T. As mentioned above, the metric standard is B=1/10 T and the American standard is B=1/12 T. The lines of 4 standard baffles of each standard are drawn in the graphic. |

|

Other types of baffles

Baffles for glass-lined tanks

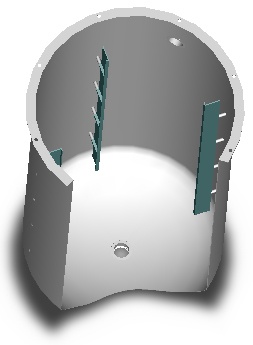

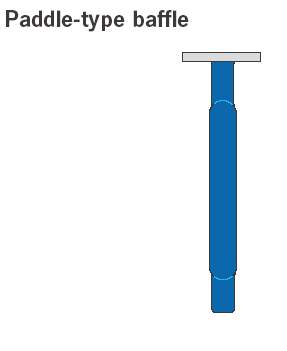

Straight flat baffles are not found in glass-lined tanks. The types

of baffles for glass-lined tanks often depend on the manufacture. In general,

though, the baffles are supported from the tank top. Baffles usually take on

names that describe what the baffle looks like, such as Beavertail

, F-baffle, and D-baffle. |

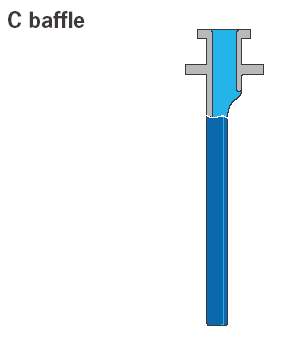

C-baffle courtesy of

Jürgen Reinemuth |

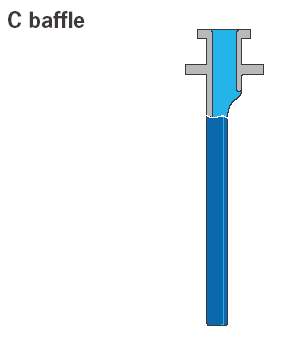

The Pfaudler Werke GmbH

in Schwetzingen,

Germany has kindly notified us that the F- and D-baffles are designs from

the past. They have come out with a brand new patent-pending

baffle design called the C-baffle, that looks to us like it would be

ideal in metal tanks, too. Like all other baffles for glass-lined tanks, it

attaches to the top of the tank through an available port. They can also add

probes to this design. The orientation of the C-baffle to the flow is

interesting and is for baffling what the

Smith Turbine or RS-6 is to

radial flow turbines.

Because of its design, the port can still be used to add liquid and gasses and

be used as a vent if required. This makes it ideal for gas-liquid reactions

in glass-lined tanks that utilize the mass transfer across the fluid surface from

the headspace, like hydrogenations.

|

Flow pattern near baffle courtesy of Pfaudler

|

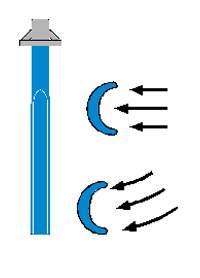

This baffle is shaped like an open C whose opening is directed against

the direction of flow of the fluid moved by the agitator. The geometry

was optimized with respect to minimized bending stress using the Finite

Element Method (FEM). Have you ever seen a flat baffle buckle and bend under

the stress of the mixing action? We have! This shape will keep that from

happening. The cw-value of a C-section is significantly

higher compared to the profile of a classical paddle-type baffle. The cw

-value is a characteristic quantity that describes the flow resistance

of a body. Higher cw-values indicate a higher resistance to flow,

and a better disturbing effect in agitating applications. The

importance of baffling has already been discussed above.

|

|

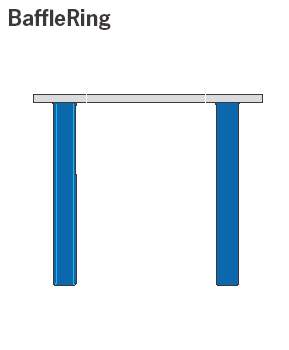

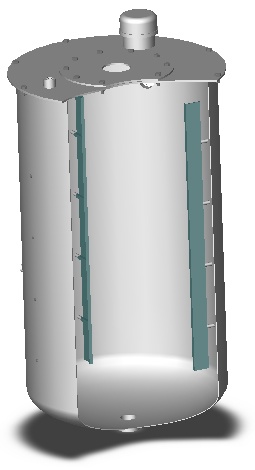

Since glass-lined baffles are attached to the tank top through an

available port, ports can be scarce, especially on the lids of small tanks.

Well Pfaudler came up with another patent-pending idea they call

the BaffleRing. It has a ring-shaped component with two C-baffles attached

to it, which is directly inserted between the lid and the lower reactor body

and fixed by the reactor clamps. Thus, all reactor nozzles are available

as process ports. Furthermore, a so far unknown level of flow disturbance

can be reached inside glass-lined reactors which reduces the mixing times

by up to 60%. Not bad! Finally a great way of reducing the swirl in

glass-lined tanks. Look at the table below how it improves mixing times!

You can read all about these innovations in a

newly released brochure from the

Pfaudler Company. This PDF-file is in English. If you want it in German

please contact Pfaudler directly.

If you reside outside of Europe and Asia and you want to know more about

this interesting development please contact

Pfaudler in the USA.

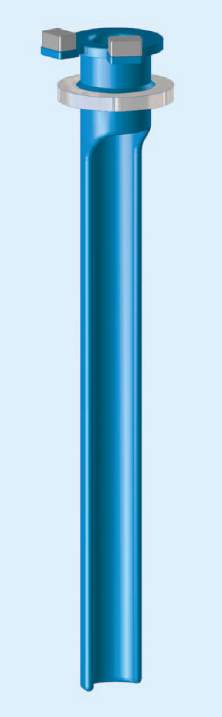

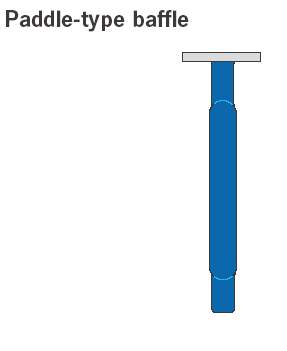

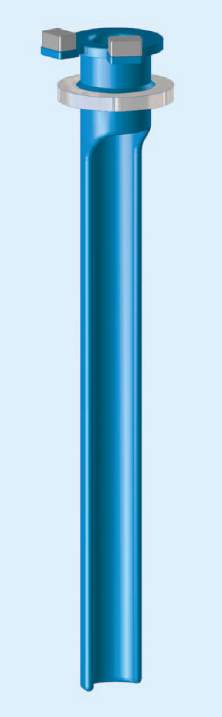

Another baffle-type is called the Quatro-Pipe. This unit is a dip pipe

with the outer shape of the classic Paddle-type baffle. Thus, the

Quatro-Pipe acts like a baffle, but offers the added value of introducing

or removing a fluid into/out of the reactor through an additional nozzle.

But think about this for subsurface aeration, hydrogenation and other

gas-liquid applications, too.

|

| |

|

Paddle-Type |

C-Baffle |

BaffleRing |

Quatro-Pipe |

Current Baffle Types

for Pfaudler Glass-Lined

Tanks |

Nr.

of

baffles |

|

|

|

|

Relative Baffling effect

4 standard baffles = 1.0 |

1

2 |

0.55

0.75 |

0.79

0.91 |

-

0.91 |

0.55

0.75 |

Relative Mixing Time

Paddle-type baffle = 1.0 |

1

2 |

1.0

- |

0.65

0.40 |

-

0.40 |

1.0

- |

| Gas sparging |

- |

surface |

surface |

surface |

sub-surface |

|

Baffles in the tank bottom

When axial flow down-pumping impellers are used, a crucifix baffle in the

base may be all that is needed. The crucifix baffle is comprised of two plates

that cross (usually in the center). They should not be placed directly on the

bottom of the tank, so that solids don't get stuck.

Baffles in horizontal cylindrical tanks also called autoclaves in the mining industry

Horizontal cylindrical tanks often have baffles at the location of the impeller shaft(s) on the curved walls. They usually come in two basic shapes, the half-moon, and the contour baffles. These types can also be placed on the dished heads of these tanks as well. They are not as affective as standard flat baffles in vertical cylindrical tanks, but are much better than nothing. It is our opinion that the optimum design of baffles for this tank geometry has not yet been made.

Baffles in side-entry tanks

A flat plate baffle in the outlet stream of a side-entry mixer can help

to straighten the flow and reduce the formation of a vortex emitting from

the impeller.

Fluid forces on baffles and baffle plates

To design an agitation system - tank, shaft, impellers, and baffles

(or baffle plate) - each component must be built strong enough to withstand

the fluid forces generated by the impellers. Many calculations and

programs are based on conservative hand-waving ideas based on the torque on

the impeller shaft times some multiplier. This really isn't necessary anymore.

The Acusolve

CFD program that we use, can

accurately determine the fluid forces on baffles, shafts, and the tank walls!

Contact us if you would like a quote to determine

the fluid forces of your mixing system.

|

|

|