CFD Technology/Outputs

Computational Fluid Dynamics can be intimidating.

It is the best example in mixing that renders itself to the age old

saying: "Garbage in is garbage out."

Computational Fluid Dynamics is an attempt to solve the

Navier-Stokes equation in mixing tanks. The outputs from these programs

are so pleasing to engineers that they are often referred to as

Colorful Fluid Dynamics. Many call CFD for mixing CFM, or

Computational Fluid Mixing. At

Mixing XIX

CFD was coined Confusing

Fluid Dynamics. A recent visitor made us aware of yet

another acronym: Color For Directors!

|

|

We have one of the best CFD (CFM) experts in the field on our team.

We use the fastest and most accurate CFD software available

(ACUSOLVE).

We have created a special user friendly layer specifically addressing

- dynamic mixing in horizontal or vertical tanks,

cylindrical, rectangular parallelepiped (box) or spherical

- dynamic mixing in pipes (also known as pipe mixers,

inline mixers, inliners)

- static mixers in pipes (also known as static mixers,

Kenics® mixers, SMX®-mixers)

- Rotor-stator mixing (also known as high shear mixers,

dispersers)

CFD can be intimidating. Done correctly, CFD can replace

experimentation. But what do all those lines and colors mean?

Are the inputs meaningful? Are comparisons made at proper

boundary conditions?

|

|

|

|

|

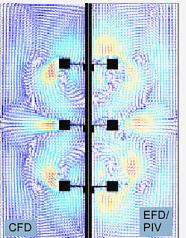

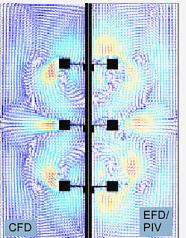

High viscosity blending with 3 Rushton Turbines using

ORCA (CFD) and compared to EFD and PIV (see definitions

below.

|

|

What conclusions should we make from these outputs? Post Mixing

has the capability of getting CFDs or CFMs done in mixing tanks,

columns, pipes, static mixers and other relevant reactor configurations.

We can also have a look at your CFDs and describe to you what they

are trying to convey. Don't draw the wrong conclusions from CFDs

or CFMs. Have an expert take a look at them. We have access to one

of the best experts in the field.

Computational Fluid Dynamics, or in this specific case,

Computational Fluid Mixing is a very powerful tool when experimentation

is either not possible, dangerous, or too expensive.

|

|

|

Ask Post Mixing for a quote on CFD experiments for your process

and reactor. We are not limited to mixing tanks. We can also do

static mixers and mixing in pipes, etc. and even fun subjects like

mixing honey in your mug of tea. The download time will be less than

2 minutes.

Have a look at some of the other CFD services we offer.

There may be other uses of CFD that you have not yet considered.

Click here for

more CFD and CFM examples.

|

|

Key Benefits

- In-depth analysis of the outputs from mixing experts,

not just CFD experts.

- Be assured that your mixing project is looked at properly.

- Proper use of physical parameters

- Focus on what is important

- Proper use of simplifications

- Explanation of the inputs and parameters.

- We use the fastest and most accurate CFD software

available (ACUSOLVE), so we can get more done in any given time.

- Mixing factors

- The CFD output is based on first principals. We do not base

our outputs on a predetermined velocity profile of a similar

impeller using laser scans, PIV (particle image velocimetry),

or EFD (experimental fluid dynamics), but the results are

remarkably similar.

- Determination of shaft torque, impeller power, and power

number, NP, is very accurate and quickly determined, unlike

other programs. Why not take us for a test!

- Predefined available static mixer elements are the most

commonly found Sulzer SMX® and the Chemineer Kenics® mixing

elements. They can be arranged in any fashion and any length.

Other elements can be designed on demand.

- Predefined available impellers are the Rushton Turbine (RT),

the pitched bladed turbine (PBT), and a generic low solidity

hydrofoil (Hyd) similar to a LIGHTNIN A310. A new program allows

us to design just about any hydrofoil (fluidfoil) you may want.

They can be arranged in any fashion on the shaft, any number

of impellers and combinations of impellers.

- We can design any other impeller for your project.

- We can design Rotor-Stators

(also known as high shear mixers, dispersers).

- We should be able to design flotation cells

(but we haven't tried yet).

- Impeller mounting can be anything you want:

- Top entering - on axis or off-axis (off-center)

- Bottom entering - on axis or off-axis (off-center)

- Angular mount - like the way most portable mixers

are attached!

- Side entering

- We can design surface aerators and submerged impellers.

The program does have a free surface model, so we can even predict

the form of a vortex, if it is important.

- Tanks can be any shape:

- Horizontal cylindrical

- Vertical cylindrical

- Rectangular parallelepiped - Box or Rectangular-

or Square-Cross-Sections

- Spherical

- Flat or dished sides or bottoms

- Scale-up, scale-down, and site transfer issues

disappear completely.

It is important to have good reliable CFM or CFD software within

which you can have substantial confidence relative to the physics of

the process. Then you can accomplish a lot of virtual testing on

the computer, before committing that design change to expensive

real experimental testing and equipment costs. This saves you much time

and money, as well as providing a better quality end product.

|

|

|