This is a continuation of the

Process Intensifier - Optimization with CFD: Part 1 paper.

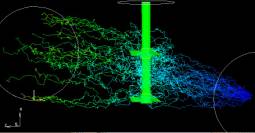

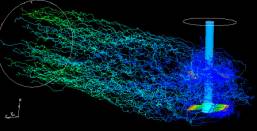

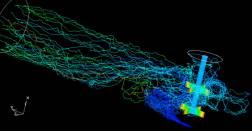

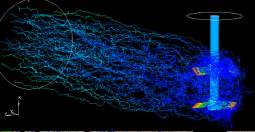

Unlike the flow pattern tracer study, this study shows the effect of mixing

in a second component (see Figures 17-18). The tracers are neutrally buoyant in

this study, but they could easily be made heavier or lighter than the bulk

fluid. The injection port of LTR and HGR is directly below the lower radial

impeller. 250 particles are injected at this point. The mean residence time of

the fluid based on volume and flow rate is 1.35 s (light-blue) at 650 GPM (148

m3/hr) and 0.80 s (blue) at 1100 GPM (250 m3/hr) for LTR and is 1.27 s

(light-blue) at 650 GPM (148 m3/hr) and 0.75 s (blue) at 1100 GPM (250 m3/hr)

for HGR. The difference is a function of the chamber volume.

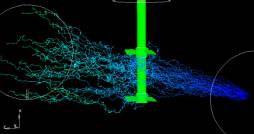

The injection port for a Lightnin Line Blender with axial impellers is

between 5-10 pipe diameters upstream. We injected it in this study at 4 pipe

diameters upstream. Injection was studied at two locations: in the center of the

pipe (250 tracer particles) and also split by injecting at the respective

heights of the impellers (125 tracer particles each). The mean residence time of

the fluid based on volume and flow rate is 2.26 s (green) at 650 GPM (148 m3/hr)

and 1.34 s (blue-green) at 1100 GPM (250 m3/hr) .

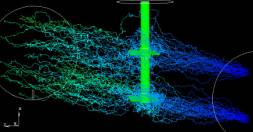

HGA has a special injection pipe. It can be seen in Figures 5, 8, 9, and 10.

It is just upstream of the impellers, right after the flow straighteners.

Injection of the tracer was made at the respective impeller heights (125 tracer

particles each). The mean residence time of the fluid based on volume and flow

rate is 1.27 s (light-blue) at 650 GPM (148 m3/hr) and 0.75 s (blue) at 1100 GPM

(250 m3/hr).

| 650 GPM |

Radial Process Intensifier |

Axial Process Intensifier |

| Lightnin |

|

|

| |

LTR – injection below lower impeller |

LTA – single injection port |

| Lightnin |

|

|

| |

|

LTA – two injection ports |

| Hayward Gordon |

|

|

| |

HGR – injection below lower impeller |

HGA – two injection ports |

|

Figure 17: Particle tracking to visualize the flow pattern.

Dark blue = 0 s, light blue = 1 s, green = 2 s, orange = 3s,

red ³ 4 s residence time. Internals other than the impellers and

shaft are not shown. |

All of these plots (Fig. 17) appear to be doing a good job of mixing in the

second component.

It is noticeable that the tracers injected in the Radial Process Intensifiers

do not get sucked up straight into the lower impeller, but first swirls toward

the back Z-plate wall of the lower chamber. That distance is less for HGR. The

colors seem to indicate that LTR is getting a more uniform distribution of the

tracer particles. Some are even making it in and out of the T-section. There

seems to be a lot of recirculation downstream of the HGR based on the variety of

colors seen there.

With a singular injection point, LT1 is able to spread the tracer particles

fairly uniform around the pipe cross section. None of the particles are making

it into the T-section and they all seem to have a very uniform residence time.

To improve on the mixing, 2 injection ports are studied at the respective

heights of the impellers. This appears to do a much better job of dispersing the

tracer particles. Some particles are getting into the T-section and they are

recirculating in there long enough to require more than 4 seconds residence

time.

HGA also does a very good job of dispersing the tracer particles about the

cross-section of the pipe. It does appear that there is some recirculation going

on, though, based on the large number of blue traces among the green at the

outlet.

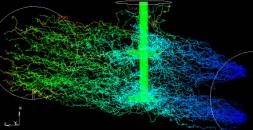

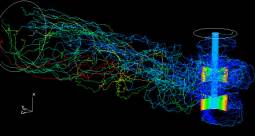

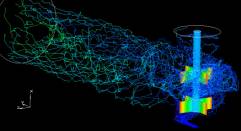

| 1100 GPM |

Radial Process Intensifier |

Axial Process Intensifier |

| Lightnin |

|

|

| |

LTR – injection below lower impeller |

LTA – single injection port |

| Lightnin |

|

|

| |

|

LTA – two injection ports |

| Hayward Gordon |

|

|

| |

HGR – injection below lower impeller |

HGA – two injection ports |

|

Figure 18: Particle tracking to visualize the flow pattern.

Dark blue = 0 s, light blue = 1 s, green = 2 s, orange = 3s,

red ³ 4 s residence time. Internals other than the impellers and

shaft are not shown. |

The most noticeable difference at 1100 GPM (250 m3/hr) (Fig 18) to the 650

GPM (148 m3/hr) case (Fig 17) is that the LTA appears to be having difficulty

staying in control of the flow pattern. With a single injection port, the tracer

particles appear to be just passing through the impeller zone. The lower

impeller pulls down some particles, and none of the particles are being pushed

up into the T-section. Two injection ports do improve the situation. The lower

impeller pulls down some particles, and some of the particles are being pushed

up into the T-section. There is a noticeable mixture of blue and green tracer

tracks in the outlet.

Continue with Impeller Flow

or

Go back to Results

or

Go back to the Title Page

|