This is a continuation of the

Process Intensifier - Optimization with CFD: Part 1 paper.

It is always important to know the pressure drop of items in

a pipeline.

These pressure drops were measured over a 78.7 inch (2 m) pipe section, which

included the Process Intensifier. The shaft of the mixer was in the exact middle

of the pipe section. Therefore, there were almost 4 pipe diameters upstream and

downstream of the mixer for this study.

Pressures computed in ACUSOLVE are formulated using equal order interpolation

with the velocity variables yielding a consistent structure, which permits and

facilitates the total formulation stability and convergence proofs. Hence, along

with the velocities, the pressures have the identical solution accuracy,

stability and convergence characteristics, including local and global

conservation, as the primary variables for velocity. ACUSOLVE admits a variety

of boundary conditions, ranging from specified velocity and mass flux

conditions, to being totally determined and computed by the solution. ACUSOLVE

can even handle the case where the momentum and energy supplied by a pumping

impeller determines the inflow / outflow of a system, including both velocity

and pressure determination. A related characteristic is that the pressure

boundary condition does not make any requirement of velocity specification, and

that in the general case, any given surface could have flow going in both

directions. In the case of the Process Intensifiers, designs may be developed

that either introduce a pressure drop, or a pressure boost (see Part 2). The

accuracy of ACUSOLVE permits the proper evaluation of the pressure state of the

system.

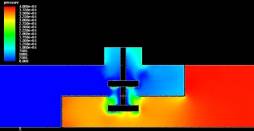

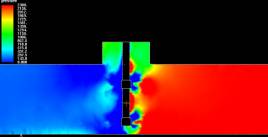

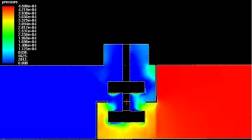

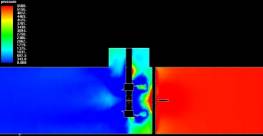

| 1100 GPM |

Radial Process Intensifier |

Axial Process Intensifier |

| Lightnin |

|

|

| |

Red = 40,000 Pa = 5.8 psig |

Red = 2,300 Pa = 0.3 psig |

| Hayward Gordon |

|

|

| |

Red = 45,000 Pa = 6.5 psig |

Red = 5,500 Pa = 0.8 psig |

| Figure

8: Pressure drop determination in the Process Intensifiers at 1100

GPM (250 m3/hr). Click on any picture for a larger view. |

The pressure drops were determined by looking at the pressure distribution

plots (Figure 8) of each device. The following pictures show the local pressure

distributions in a vertical plane directly through the middle of the pipe at

1100 GPM (250 m3/hr) flow. The scale is not the same for each device, but red

always corresponds with the highest pressure (inlet) and blue always corresponds

with the outlet pressure. Blue is in each case = 0, meaning that this shows

pressure above the outlet pressure (gauge pressure). This form of representation

makes it very easy to determine the pressure drop. The numbers are in Pascals.

The maximum value on the scale (red) is thus the pressure drop from inlet to

outlet, which is over a 78.7-inch (2 m) section. The values of all the pressure

drops are in Table 4.

| PSI (Pa) |

Radial Process Intensifiers |

Axial Process Intensifiers |

| |

Lightnin – LTR |

Hayward Gordon – HGR |

Lightnin – LTA |

Hayward Gordon – HGA |

| Click on any picture for a bigger picture |

|

|

|

|

| 650 GPM |

2.8 (19305) |

3.9 (26890) |

0.15 (1034) |

0.4 (2758) |

| 1100 GPM |

5.8 (39990) |

6.5 (44816) |

0.3 (2068) |

0.8 (5516) |

| Table 4: Pressure drops across the

Process Intensifier in PSI (Pa). |

The pressure drops (Table 4) appear to be directly related to the power

consumption of the impellers but are obviously a stronger function of the

overall flow rate through the pipe. The pressure drops at 650 GPM (148 m3/hr)

are approximately ½ the values at 1100 GPM (250 m3/hr). The LTA at 1100 GPM

(250 m3/hr) is particularly low probably because it is "flooded" by

the cross flow and has little affect on disturbing the flow through the pipe.

The pictures for 650 GPM (148 m3/hr) is not shown.

Continue with Pressure

Distribution

or

Go back to Results

or

Go back to Title Page

|